We had hoped that the floor would be fairly straightforward and simple. I suppose it was, but there were a few things that needed doing that we didn’t know would need to be done.

Example: the two pictures below. It looks like John (our expert floor genius… he did the VCT in our loggia & hallway) is smearing a bunch of dirty cement on our crisp & clean plywood subfloor. Well he is because unlike the particleboard sheets he wanted us to use as a subfloor, plywood has grain issues and a few of the joints were either too wide or were splintering a bit.

(We elected to use 1-1/16″ tongue & groove plywood instead of particleboard mostly because of structural issues… there was a large crawlspace access hole where the fridge needed to go and a mysterious crawlspace hole in the family room. Frame in a few supports, lay down the super heavy duty plywood and that’s one sturdy floor!)A little dry-time and sanding and the floor was ready for Armstrong VCT.

After the VCT was down… let’s polish that stuff! We found a great floor guy (who also works the pro-desk at Home Depot) who does floors on the side. We had him strip & polish the new floor AND the now dirty loggia/hallway floors in hopes that the transition between the loggia and the kitchen would be as seamless as possible.

It reminded me of a pint-sized Zamboni. this machine did the finish stripping and I think layed down some of the wax… I hear it took 6 coats of high gloss wax!!!

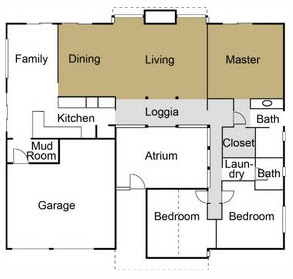

And to bring out that shiny finish, here’s a high-speed buffer taking care of business in the loggia near the atrium.

The gleaming finished floor. It almost looks wet!!! AND it’s super slippery when wearing socks (which makes it perfect for moonwalk lessons).